GKS ENGINEERED CABLE TRAYS

In modern industrial plants, the ambient conditions represent a major danger to power, data and control cables. Soiling, vibrations and industrial influences create a tough environment. This is why it is even more important for the electrical installations of machines and plants to withstand the different loads reliably. The GKS Engineered cable tray system from OBO offers an open space for routing cables, protecting them against corrosion and also allows the heat from the cables to dissipate. GKS Cable trays are subjected to corrosion category standard DIN EN ISO 12944 and classification of corrosion resistance according to IS/IEC 61537.

Surfaces for any area of application

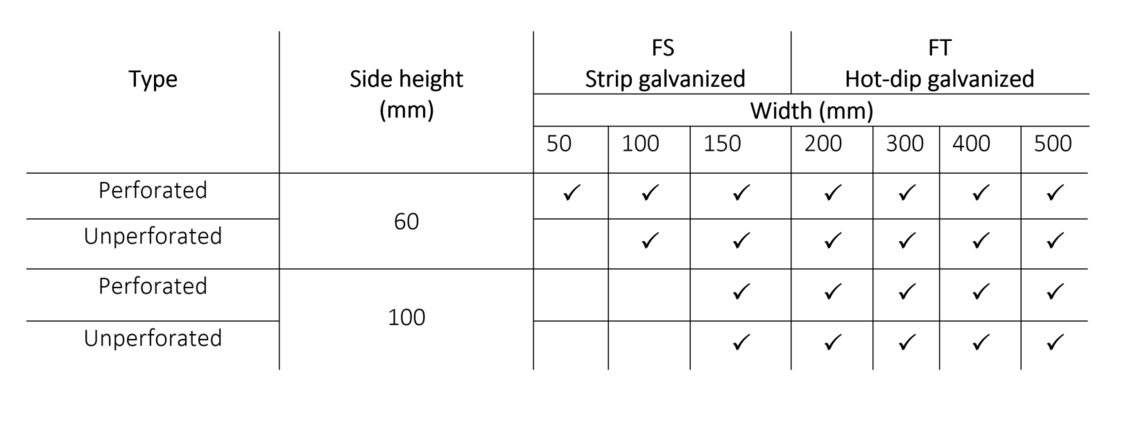

The GKS cable trays is available in two different surface versions. As a Post-galvanised variant (FT), it is designed for industrial environments and can be used in machine and systems construction. For interior areas without particular requirements, the Pre-galvanised surface (FS) is preferred.

Which variants are available?

Special features

- OBO GKS cable trays are engineered to perfection to achieve better performance and rigidity.

- Confirms to the Limit of Deflection with 1.7 times safety factor.

- Safe Working Load chart for support distance up to 2.5 meters.

- Uniform finish and highest quality through completely automated manufacturing process.

- Perforated and Unperforated cable trays in Strip and Hot dip galvanized versions.

- Available in side heights of 60mm and 100mm with widths from 50mm to 500mm.

- Snap-fit covers for ease of installation and maintenance.

- Wide range of accessories for customized & weld free installations.

Applications

Strip Galvanized

- Indoor Use

- Dry atmosphere in the room

- No aggressive action

- Hazardous substances

- Textile Industry

Hot-dip Galvanized

- Outdoor Areas

- Power plant construction

- Plant & Mechanical Engineering

- Oil & Gas Industry

- Mining

- Process Industry (Steel, Paper, Cement, etc.)

- Automobile Industry

- Rubber Industry

BET Testing

All the OBO articles & systems are subjected to practical load testing. The basic principle for the tests of the OBO cable support systems are as per IS/IEC 61537. After the load test, the maximum load capacity can be determined for each component, depending on the support distances and specific article parameters, such as component dimensions.

- TDAP Certified

- VDE Certified

- ISO 9001, 14001, 50001 Certified

- Over 100 years of experience